practical applications of charpy impact test|charpy impact test standard : manufacturer Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its . webVeja a previsão do tempo para os próximos 15 dias em Brusque, com informações sobre temperatura, chuva, vento, índice UV e alertas meteorológicos. Saiba se vai fazer .

{plog:ftitle_list}

WEBVelkommen til ORIS Tandlægerne Slotsgade i Odense. På vores klinik, beliggende blot et stenkast fra Odense Banegård, finder du et tandlægefællesskab med højt fagligt niveau, en god og afslappet stemning, og ikke mindst et ønske om at finde den bedste løsning for dig som patient. Det er vigtigt for os, at du oplever dit besøg positivt.

charpy impact test standard pdf

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact test results help manufacturers and engineers determine whether the material is suitable for its .The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its . The Izod impact test involves striking a notched specimen with a pendulum. The energy required to break the specimen is measured and reported in units of joules per meter. The test measures the energy absorbed by the .

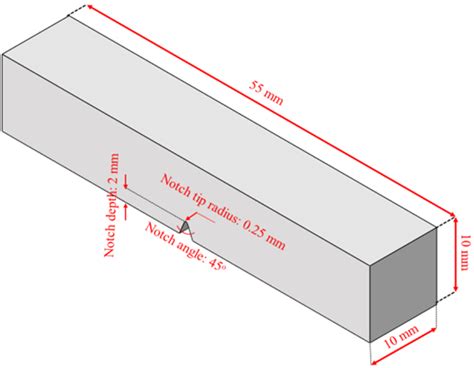

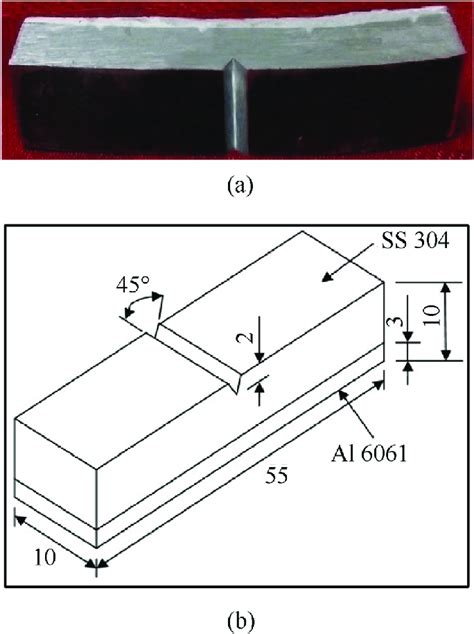

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.The widely used Charpy impact test is a standard way to assess toughness quantitatively in notched specimens. In this test a standard bar specimen, with a square cross section and a V .Conducted across various industries, this test provides critical insights into how a material withstands sudden, dynamic loads. In this guide, we will delve into the essence of the Charpy impact test, exploring the purpose, procedure, .

The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture. The .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a .The Charpy impact test is still used throughout sectors to assess material toughness, from construction and manufacturing to engineering and beyond. This test offers practical insights into how materials respond to sudden, dynamic .The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. Fig 1: Charpy Test Apparatus. This test determines the amount of energy absorbed by a material during fracture. This absorbed energy is a measure of a given material’s notch .

The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away .Question: PROBLEM 10. Describe the practical engineering applications of the Charpy impact test. List the uses for recorded impact test data. Show transcribed image text. Here’s the best way to solve it. Solution. View the full answer. Previous question Next question. Transcribed image text: PROBLEM 10. Describe the practical engineering . ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the fracture behavior changes as the temperature drops and the fracture type changes from ductility to brittleness.

An Izod impact testing apparatus — which is essentially identical to a Charpy impact testing machine — is used to determine Izod impact strength. The primary differences between the Izod and Charpy impact tests are the size of the test specimen, how it is restrained, and which side is struck by the pendulum hammer. This blog aims to explore the fundamental principles behind the Charpy Impact Test, its practical applications, and the variety of testing machines that perform this essential procedure. By understanding these elements, readers will gain insights into how material toughness is assessed and the significance of these tests in ensuring the .

In 1922, the American Society for Testing and Materials (ASTM) organized a symposium on impact testing, and 10 years later, the first ASTM E23-33T “Tentative Method of Impact Testing of Metallic Materials” was finally released, specifying the use of a pendulum, both Charpy and Izod, a V-notch specimen, and a measurement system.

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and .

The impact strength of a material is an important characteristic for applications in pipeline construction and shipbuilding. The test method is also described and determined in ASTM E23. The ISO standard is identical to the European standard (EN ISO 148-1). . In a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a .

International Journal of Engineering Research and Applications www.ijera.com ISSN: 2248-9622, Vol. 11, Issue 10, (Series-IV) October 2021, pp. 59-63 . the Charpy Impact Test to develop the most ideal approach to materials testing and selection. The author found Metallic materialsThe Charpy impact test is a simple test designed to evaluate materials under dynamic loading conditions. ASTM E23‐07 í, Standard Test Methods for Notched Bar Impact Testing of Metallic Materials, outlines the test method as well as specimen size and geometry. Typically, CharpyIt is a pendulum-type single-blow impact test that involves the use of a notched test piece, which will be tested by either of the two techniques, namely the Izod test and Charpy test. In this scenario, Tinius Olsen comes as a game changer with its impact testers with a testing capacity of up to 542 J, quality testing, superior data acquisition .

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps .

charpy impact test standard

Charpy impact test results are measured in joules, the SI unit for energy. This is simply the amount of work performed by a 1-newton force pushing a sample by 1 m in the direction of the force. This value can be used to .Studies involving the application of the instrumented Charpy impact test are presented. The studies were concerned with the effect of strain rate, alloying, and irradiation on the ductile-brittle transition temperature (DBTT) and fracture .

(using Rockwell testing) and impact (using Charpy testing). Chauvenet’s Criterion will be applied to identify . experiments that replicate, as nearly as practical, the service conditions. Factors to be considered include . compressive, or shear, and its magnitude may be constant with time, or it may fluctuate continuously. Application .In a number of applications, the enhanced resistance that may develop during about one plate thickness of crack extension from a sharp notch is of major interest. . At WMT&R Izod and Charpy impact testing are performed on instrumented machines capable of measuring less than 1 ft-lbf to 300 ft-lbf at temperatures ranging from -320°F to over .Practical Applications; Introduction. One common high-strain-rate test is the Charpy impact test. It calculates the energy a material absorbs during fracture. The amount of energy absorbed indicates how tough the material is. It is a tool for researching the ductile-brittle transition that is dependent on temperature.The Charpy impact specimens of each material are immersed in a bath for 10 minu tes to reach thermal equilibrium at five separate temperatures ranging from 110oF (-79oC) to 212-oF (100oC). The specimens are quickly transferred to the Charpy testing machine, fractured, and the impact energy is measured. After

Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3). The Charpy impact test, just like any impact testing method, determines the toughness of materials by measuring the amount of energy absorbed by a specimen as it fractures while being struck by a . In this blog we will discuss impact testing procedure and the difference between Charpy and Izod Impact Testing. Home; Products. Special Offers. Fully Automatic Shore/IRHD Hardness Tester . (stress) or swelling (strain) mode, is fully automatic for a practical and accurate test execution with more reliable test results. . Standards and .

phr Charpy NMFE Charpy NMFE Charpy NMFE Charpy NMFE 4.7 54.9 926 61.5 892 66.8 953 55.7 945 5.2 53.5 942 62.7 956 68.3 961 55.8 911 Fracture toughness testing standards such as ASTM E1820 or ASTM E 1921 ISO 12350 are seldom used in practice. Estimates of K Ic or J Ic by empirical correlations with classical Charpy impact tests are much more popular and often preferred. The reasons for this unsatisfying situation is that the standard procedures of fracture toughness testing are much . Test criteria for Charpy V-notch impact testing usually involve (i) a minimum impact energy value, (ii) shear appearance of fractured test bars expressed in percent, and (iii) lateral expansion. For steels, the minimum acceptable values generally specified for these three evaluation methods are 20 J, 50 % shear, and 1.3 mm respectively.

harvestmaster temperature on grain moisture meter

Mia Khalifa is one sexy Lebanese porn star you have to discover. Watch her amazing free porn videos on Pornhub. This is one video vixen to enjoy cumming to.

practical applications of charpy impact test|charpy impact test standard